Orthopaedic implant surgeries, such as hip and knee replacements, are common procedures performed daily around the world. Bacterial colonization of the implants, however, can lead to complications, implant failure and, in about 7% of cases, necessitate revision surgery. Current infection control methods rely on antibiotics, but are far from optimal. So a team at Washington State University has developed a novel titanium (Ti) alloy to create load-bearing implants with an inherent antibacterial response.

“Infection is a problem for which we do not have a solution,” explains corresponding author Amit Bandyopadhyay in a press statement. “In most cases, the implant has no defensive power from the infection. We need to find something where the device material itself offers some inherent resistance – more than just providing drug-based infection control.”

Orthopaedic implants are typically made from the Ti alloy Ti6Al4V (containing 6% aluminium and 4% vanadium), which offers excellent mechanical performance and corrosion resistance, but is less biocompatible than commercially pure Ti (CpTi). In this latest work, Bandyopadhyay and colleagues aimed to design an alloy that combines the biocompatibility of CpTi with the mechanical strength of Ti6Al4V.

The researchers used 3D printing techniques to create Ti3Al2V, an alloy with 3% Al and 2% V. They found that minimizing the Al and V components did not compromise the material’s mechanical properties. In terms of strength and modulus of elasticity, Ti3Al2V performed significantly better than CpTi, without considerable degradation in strength from that of Ti6Al4V.

The team notes that the modulus of elasticity observed for porous Ti3Al2V was closer to that of natural bone than commercially used alloys. This is important as this is the strongest determining factor for long-term fixation and healing of a surgical implant. Both Ti6Al4V and Ti3Al2V samples exhibited high fatigue resistance, surviving 10 million cycles at 21% of their respective compressive yield strength without failure.

Antibacterial action

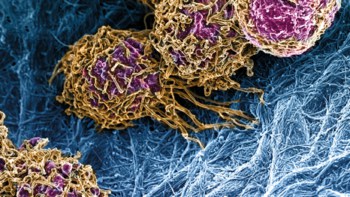

For fast healing and successful long-term integration of a metallic implant, it’s vital that bone tissue covers its surface faster than any contaminating bacteria. To protect the implant against bacterial infection, the researchers added 3 wt.% copper (Cu) to the new alloy. Copper is known to exhibit antibacterial activity, likely due to contact killing, in which bacteria coming into close contact with Cu surfaces are rapidly eliminated via cell wall rupture and disruption of the cell membrane.

To assess the bacterial inhibition afforded by adding Cu, the researchers tested the various materials against two bacteria that commonly infect implants: S. aureus and P. aeruginosa. The Ti3Al2V–3Cu alloy exhibited roughly 80% higher antibacterial efficacy than CpTi and Ti6Al4V against these two high-risk bacterial strains. For S. aureus, which is responsible for around two-thirds of implant infections, Ti3Al2V–3Cu killed 87% of the bacteria after 24 hr.

While Cu imparts microbial resistance to Ti3Al2V alloys, it could also alter bone response when implanted in vivo. To compensate for any potentially compromised biocompatibility and enhance healthy growth of surrounding bone tissue into the implant, the team added 10 wt.% tantalum (Ta) to create the alloy Ti3Al2V–10Ta–3Cu.

“A multifunctional device providing both infection control and good bone tissue integration can provide a paradigm-shifting tool to orthopaedic and dental clinicians,” co-author Susmita Bose tells Physics World. “Because infection is such a big issue in today’s surgical world, if any implant enhances biocompatibility with good bone quality and does infection control, there’s nothing like it.”

In vivo implants

Next, the researchers assessed the in vivo performance of the various Ti-based materials, implanting samples of six different materials (CpTi, Ti6Al4V, Ti3Al2V, Ti3Al2V–3Cu, Ti3Al2V–10Ta and Ti3Al2V–10Ta–3Cu) in the leg bones of rats. After six weeks, they euthanized the rats and examined the implant–bone sections. Histological analysis revealed no sign of inflammatory response or infection for any of the implant materials, suggesting non-toxicity. The team also saw evidence of tissue ingrowth into the implant and new bone formation for all compositions except Ti6Al4V.

Examining the host tissue response to the alloys revealed that adding Cu to Ti3Al2V delayed the onset of osseointegration compared with Ti3Al2V alone. However, the researchers note that adding Ta to Ti3Al2V–3Cu “reverses the delayed onset of osseointegration and shows the overall best performance among all six compositions”.

Smart stitches could prevent infections at surgical sites

“Our best-performing Ti3Al2V–10Ta–3Cu alloys offer microbial resistance, enhanced biomechanical performance and enhanced biocompatibility compared to CpTi, Ti6Al4V, Ti3Al2V–3Cu alloys alone,” the team concludes. “Thousands of patients have reported implant failures due to external causes such as microbial infection, which a Ti6Al4V implant is not tailored to overcome. We feel a material like Ti3Al2V–10Ta–3Cu could only improve patients’ postoperative quality of life and reduce revisional surgeries that arise from multiple scenarios, including bacterial infection.”

The study is reported in the International Journal of Extreme Manufacturing.