A new single-mode optical fibre made from sapphire rather than the usual silica can withstand temperatures of over 2000 °C as well as high levels of radiation. Although the fibre’s length is currently limited to 1 cm, its developers at the University of Oxford, UK, say that the technique they used to construct it could be extended by up to several metres, making it useful for remote sensing in ultra-extreme environments.

Optical fibres usually consist of a central core surrounded by cladding. Because the core has a slightly higher refractive index than the cladding, light travels down the fibre by undergoing near-total internal reflection at the core/cladding interface. In fibres with relatively large cores (around 50 µm), the extra space allows light to follow paths of varying length, meaning that many different wavelengths of light get reflected at once. Such fibres are termed “multimode”, and each mode has a different effective refractive index. In contrast, fibres with narrower cores (around 9 µm) can support a single mode, such that the light follows just one path.

From very multimoded to single-mode sapphire fibre

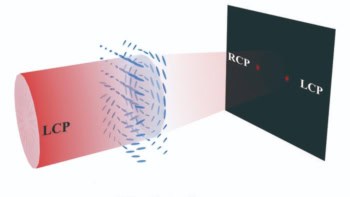

Optical fibres made from sapphire differ from this design in several ways, explains team member Mohan Wang. Rather than having a core and cladding, sapphire fibres are made from a solid single crystal of the material, and light is guided by the interface between the sapphire and the surrounding air. The relatively large (between 60 and 425 µm) diameter of the crystal means that sapphire fibres are highly multimodal: a typical 75 µm fibre may contain 20,000 modes. Light in each mode propagates at a different speed, resulting in the distortion of optical signals.

In the new work, Wang and colleagues found a way to make a single-mode sapphire fibre by writing a channel along the length of a 425 µm-diameter fibre such that the light is contained within a tiny cross-section less than 10 µm in diameter. The researchers did this by choosing a point within the sapphire fibre cross-section to be the “core”. They then exposed the sapphire around this region to extremely short (170 femtoseconds) pulses of laser light, effectively forming a cladding by lowering the local refractive index.

“We achieved this by writing a series of stripes along the length of the fibre, starting at the bottom and working our way around the core to the top,” Wang explains. A significant challenge, he continues, is that the sapphire has a high refractive index and is not flat. Instead, its cross-section resembles a rounded hexagon, giving rise to significant distortion when the researchers attempted to focus light inside the fibre and forcing them to use adaptive optics to correct for it.

A Bragg-grating-based sensor

The researchers used this laser-writing technique to create a so-called Bragg grating, which is a periodic variation of the refractive index along the length of the fibre. “If the fibre is single-mode, the fibre Bragg grating reflects light at a specific (Bragg) wavelength according to the pitch of the grating and the effective refractive index,” Wang explains. “Changes in temperature and strain affect these properties and can be measured from the wavelength of the reflected light, allowing the fibre to be used a sensor. Previous attempts at Bragg gratings in multimode sapphire fibre had a multiple reflection peaks – one for each mode, resulting in measurement uncertainty.”

The Oxford team is now working on making its sapphire fibres longer – a few centimetres to begin with, but ultimately up to several metres, study leader Julian Fells says. Longer fibres could contain multiple sensors and might be used to measure temperatures throughout the volume of a jet engine, where temperatures easily exceed the 1000 °C maximum for silica fibres. Fells suggests that data from such measurements could help reduce nitrogen dioxide emissions by altering engine conditions mid-flight or improving overall efficiency. “We are also exploring opportunities to instrument an aero-engine test-rig with our partners Rolls-Royce and Cranfield University,” he says.

Using physics to fuel fibre-optic innovation

Other possible applications for the fibre include sensing in environments with high levels of radiation. “Since sapphire is robust to radiation, it has an advantage over conventional silica fibres, which are damaged by radiation,” Fells tells Physics World. In the future, the team plans to supply devices to MDA Space and Robotics and to the UK Atomic Energy Authority for evaluation by its Remote Applications in Challenging Environments (RACE) division. “Sapphire is also transparent over a much wider wavelength than silica, out to the mid infrared, so it is of interest for gas sensing using spectroscopy,” Fells concludes.

The fibre’s construction is described in Optics Express.