The introduction of MRI-guided radiation therapy systems offers the promise of high-precision, real-time image guidance during irradiation. With these next-generation treatment systems now entering the clinic and starting to treat patients, there’s a parallel need for effective and efficient quality assurance (QA). Modus QA, a specialist in image-guided radiotherapy phantoms, is meeting these emerging needs with its QUASAR MRID3D geometric distortion analysis system.

Images recorded by any MR scanner, including MR simulators and MR systems integrating a linac, will suffer from some level of geometric distortion. Such distortions can arise due to inhomogeneity in the main magnetic field or from nonlinearity in the gradient coils. And while manufacturers supply distortion correction algorithms to apply to their systems, these are based on factory measurements and cannot account for the specific environment in which the scanner is installed.

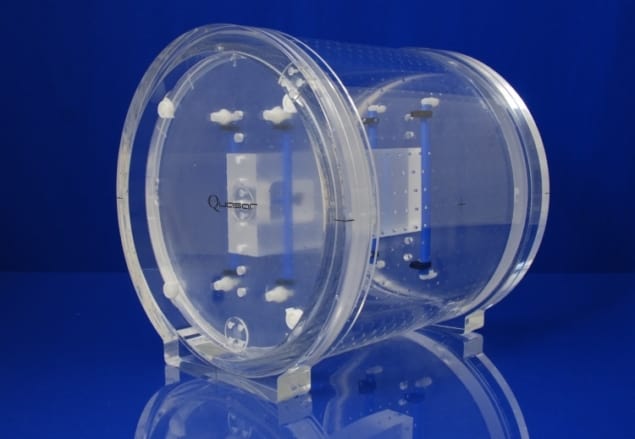

Enter the QUASAR MRID3D, which can measure both the main field inhomogeneity and the gradient nonlinearity, reporting the results separately as geometric distortion vector fields. The system comprises the phantom itself – a lightweight hollow acrylic cylinder containing 1502 precisely machined fiducial markers filled with mineral oil (the control points) placed around the phantom boundary – plus the image analysis software.

“We are finding that the greatest demand for the QUASAR MRID3D is for use with MRI-Linacs for guided radiotherapy treatment,” said Enzo Barberi, director of MR product development at Modus QA. “Our device is being used on several MRI-Linacs worldwide at early adopter sites, and also selected by MRI-Linac manufacturers who have either purchased or are evaluating the phantom. Another key application is within MR simulation, where MR images are used for radiotherapy planning.”

At the Henry Ford Cancer Institute in the USA, for example, the team is evaluating the QUASAR MRID3D for distortion characterization in its ViewRay MRIdian MRI-Linac. “The phantom will be used to benchmark our systems against other MRI-Linacs; we are also exploring its use for routine distortion assessment,” explained Carri Glide-Hurst, director of translational research in the department of radiation oncology at the Henry Ford Cancer Institute.

“The phantom has intelligent design features, such that it is lightweight, easy to setup and has excellent interactive software to analyse different sources of distortion,” Glide-Hurst added. “Previous work by our group showed that gradient non-linearity distortions, even after vendor corrections are applied, are non-negligible and may require corrections in an MR-only planning workflow. This emphasizes the need to have the proper phantoms and robust software to assess this distortion. The QUASAR MRID3D meets this need with ease.”

System development

Modus QA realized back in 2010 that MRI-guided linacs were being developed and that, once implemented in the clinic, would present specific QA requirements. The company also recognized that GRID phantoms – conventionally used to measure image distortion in MR scanners – would be either too small or too heavy for such applications, as well as highly expensive to manufacture.

As such, Modus QA teamed up with medical physicist Teo Stanescu from the Princess Margaret Cancer Centre in Canada to develop a completely new design of phantom, along with software to measure MR image distortion using a novel approach based on the harmonic analysis method.

Harmonic analysis is a well-established mathematical tool used to solve electromagnetism problems with well-defined boundary conditions, for example MRI gradient coil design, as well as B0 shimming. The QUASAR MRID3D extends this approach by measuring the boundary condition on the phantom and then using harmonic analysis to calculate the magnetic field distortion inside.

“We take an MR image of the phantom and if there is distortion on the boundary, the control points in this image will have shifted,” Barberi explained. “The software automatically locates the control points and compares them against the CAD files. The differences in their locations is the distortion vector field on the surface, which provides the measured boundary condition. The software then uses harmonic analysis to calculate the entire 3D distortion vector field within the phantom boundary.”

Lighter and faster

The QUASAR MRID3D uses far fewer control points than the 5000 or more required in an equivalent-sized GRID phantom. As well as reducing the weight, this design also enables faster QA. “Speed is a very important component of QA,” noted Barberi. “If we can achieve accurate analysis in a shorter time span, sites are more likely to perform regular QA.”

With scan times as low as 3-5 minutes at 3T, the QUASAR MRID3D process involves set-up, scanning, data transfer and data analysis in less than 10 minutes. As such, says Barberi, some sites are using the phantom every other week to monitor gradient coils and field inhomogeneity. “This was a suggestion from some of the early MRI-Linac adopters, who have implemented this in their QA programme. Our solution meets the demand for fast, accurate analysis with efficient workflow,” he explained.

Another team currently working with the QUASAR MRID3D is the MR Linac group at The Institute of Cancer Research, London, which is using it mainly for QA of their Elekta MRI-Linac installation. “Since the system has received several hardware upgrades, we tried to assess their impact on the geometrical distortions,” explained MR physicist Andreas Wetscherek. “We have used the phantom on clinical systems too, to assess whether the vendor-provided distortion correction is sufficient for radiotherapy applications.”

Wetscherek says that the group was looking to replace an old in-house distortion phantom with one that covered a large field-of-view and, importantly, was supplied by an independent company rather than the scanner manufacturer. “We were attracted by the spherical harmonics concept of the MRID3D and convinced by the expert knowledge of the Modus QA representatives,” he told medicalphysicsweb.

Elsewhere, Rob Tijssen from UMC Utrecht in the Netherlands is using the QUASAR MRID3D as an independent check on vendor-supplied geometric QA solutions. “We use this clinically on our Philips Ingenia MR-RT systems,” he said. “We have also been using it in a multi-institutional MRI QA study, in which we are benchmarking the Elekta MRI-Linac systems that are currently installed at the different consortium sites.”

Tijssen also emphasized the importance of being able to perform measurements over a large field-of-view, as enabled by the MRID3D phantom. “We have a well-established working relationship with Modus QA and they have been very responsive to our feedback, which is also an important factor to us,” he added.

Future proofing

Following the launch of QUASAR MRID3D at the start of 2016, Modus QA has implemented software updates roughly every six months. The company has introduced several new features, such as 3D visualization tools with a region-of-interest selector for users to specify custom volumes in which to characterize distortion. “Another new feature in development will give users the ability to define distortion levels that they consider acceptable and the software will report the volume that conforms to that requirement,” said Barberi.

Looking further ahead, as the emerging MRI-guided radiotherapy systems continue to evolve, the associated QA must develop alongside. Already, some manufacturers are looking to add functional imaging capabilities to their MRI-Linacs, such as diffusion weighted imaging and diffusion tensor imaging. In such applications, the diffusion coefficient is particularly sensitive to gradient nonlinearities.

“There is a need for a tool that can measure and output the spherical harmonic coefficients, then you can measure gradient nonlinearities specifically on your system,” Barberi explained. “This provides a much better diffusion coefficient correction technique. That’s something that we are also working on.”

Another future project involves using mathematical techniques to extend the harmonic analysis outside of the control point boundary. While a typical treatment volume will be well contained within the phantom volume, some specialists or device manufacturers are interested in measuring system performance outside the region of typical use. “This is something that OEMs have asked us about,” said Barberi.

“The Modus QA team is constantly trying to improve the software and adding new features that are requested by the users,” added Wetscherek. “I see the strengths of the QUASAR MRID3D in MRI for radiotherapy, where high spatial accuracy and confidence is relevant, or in centres with many different MRI scanners.”

- Individuals quoted are sharing their own views, not necessarily those of their organizations.