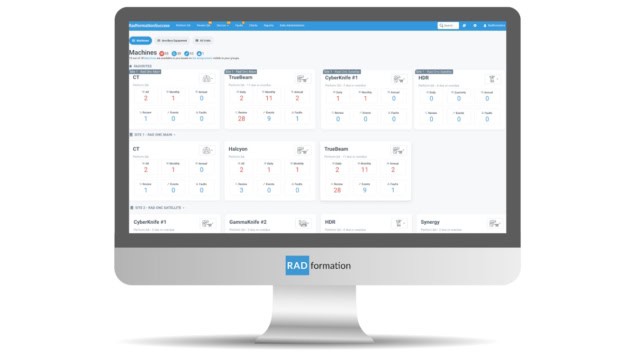

RadMachine software enables radiotherapy clinics and diagnostic centres to manage their quality assurance tasks on a single cloud-based platform

When the Hôpital de la Tour in Switzerland recently restructured its radiation therapy services, it brought in a completely new medical physics team. These physicists were tasked with revising all of the hospital’s radiotherapy processes, including the machine quality assurance (QA), without interrupting clinical activities.

To deliver a seamless changeover, the team needed to find a comprehensive QA system that could effectively manage the department’s suite of radiotherapy treatment and simulation devices. Ideally, the software would be simple to use, fast to deploy, and able to perform all of the required QA and quality control (QC) tasks from a single platform.

The answer lay in RadMachine – a complete cloud-based QA platform from oncology software company Radformation. RadMachine provides machine QA for all therapeutic and imaging systems, as well as ancillary equipment, integrating all of the data into a simple, centralized hub. The software enables users to review multiple QA data streams at once and provides detailed reports to help track device performance over time.

“When we arrived in this centre, it was challenging because the previous physicists left before our arrival. We found lots of home-made QA solutions, but these were unusable without knowledge transfer, so we had to quickly implement a new QA system,” explains Jarno Bouveret, medical physicist at the Geneva-based Hôpital de la Tour. “We were looking for next-generation software and we found RadMachine, which we are now using. It has merged all of the QA into one platform, it’s really nice software.”

One of the first tasks was to perform the standard tests required to comply with Swiss legislation. “RadMachine includes all of these tests, and Radformation helped us to adapt it, so it was really fast and easy for us to implement,” says Bouveret. He notes that the software came preconfigured – he and his colleagues just needed to perform some verification checks before customizing the QA processes to meet their needs. “It’s simple in RadMachine to just select different tests and merge them into a common test list,” he explains.

The team has been using RadMachine for over a year now – for machine QA of the department’s two radiotherapy treatment devices, as well as its CT, PET/CT and MRI simulation systems. Bouveret points out that the software’s inherent automation has helped to simplify the daily QA workload. For example, users can create a checklist of QA validation tests that the therapists complete each day. If all the tests are passed, RadMachine validates the QA automatically; but if one fails or a query is flagged, the software alerts the physicist to check it further. Likewise, if the daily QA has not been performed at the usual time, RadMachine will send an email alert.

Bouveret also works within an imaging centre at a different hospital, where much of the QA is delegated to an external company that just sends over reports. He thinks that switching to RadMachine could enhance the QA process here too, by providing greater insight into erroneous measurements, for instance, and tracking QA results over time. “I will try to import it into this other hospital, to show how good it is and what benefits it could offer,” he adds.

Designed for imaging

Meanwhile, at the University Hospitals Health System in Cleveland, Ohio, medical physicists are already utilizing RadMachine within the centre’s diagnostic imaging department. “Currently, we’re using RadMachine to record and analyse our CT quality control data and our MRI quality control data,” says Nichole Harris, a diagnostic medical physicist. “It serves as an electronic QC record and it also helps us to maintain compliance with different regulatory organizations by having records readily available.”

Harris explains that the hospital selected RadMachine due to its flexibility, its cloud-based architecture, and the availability of single sign-on features for IT integration. Another selling point was the availability of Python and associated libraries for custom test scripting. While Harris and her team have not exploited this scripting facility yet, she emphasizes that it is “something we’re looking forward to working on in the future”.

With RadMachine in operation for approximately six months now, Harris says that one valuable feature that’s emerged is the software’s ability to analyse the test data in detail and look for trends. “We are also able to produce compliance reports for different regulatory organizations, and to really see the enterprise as a whole,” she says.

RadMachine also provides automated exception reporting. “We no longer have to check every machine, every day,” Harris explains. “Our end-users perform the daily QA tests, record the data, and then RadMachine will notify the physics group immediately if something needs attention.” This approach frees up the medical physicists to concentrate on the areas where they can make the most impact, such as correcting any anomalies and focusing on the areas required to maintain compliance.

In addition to the daily QA, the team uses RadMachine to approve quality control following major system repairs, where it helps to minimize clinical downtime. Harris adds that the software’s flexibility enables them to customize it for subtle differences between machines or manufacturer’s QA requirements. “It’s built for imaging, so it’s set up in a fashion that’s applicable to our task and strikes the right balance in terms of scalability and efficiency,” she says.

System support

When the UH Seidman Cancer Center first deployed RadMachine, the team at Radformation helped set up the software to work with their imaging systems, as well as helping Harris and her team to define the overall structure for implementation. “When there were questions about the logic or nuances of the system, they responded in a quick fashion to help us resolve these issues and get the system set up,” Harris explains. “They were quite the asset in terms of the single sign-on integration with our IT organization.”

Bouveret agrees that Radformation’s support team was a great help in implementing the new software. “I have had a lot of contact with them,” he says. “They have helped us to customize some image analysis to respond to the Swiss legislation. Every test we have asked for, they have created for us.”

Looking ahead, Bouveret says that the Hôpital de la Tour plans to begin new treatments such as radiosurgery, which will require the development of specific QA procedures. “We will be able to create our own tests by coding in Python and then we can just import it into the RadMachine software,” he tells Physics World. “So this will be really interesting for the future.”

- Visit Radformation at the AAPM Annual Meeting, booth #807, to see a demonstration of RadMachine.